The saying ‘Don’t judge a book by its cover’ is not applicable in the business world today, with customers judging almost all products and companies based on the package used. Also known as the silent seller, packaging is an essential part of any product, whether to protect and transport, or to display and attract. Packaging is the final marketing message and impression that a company leaves on its target market.

Corrugated board is one of the most commonly used materials for packaging. Manufacturers customize corrugated packaging to meet the exact needs of users to ensure the right product-packaging fit and convey the right brand image. Below are some important tips on what to consider when purchasing corrugated packaging.

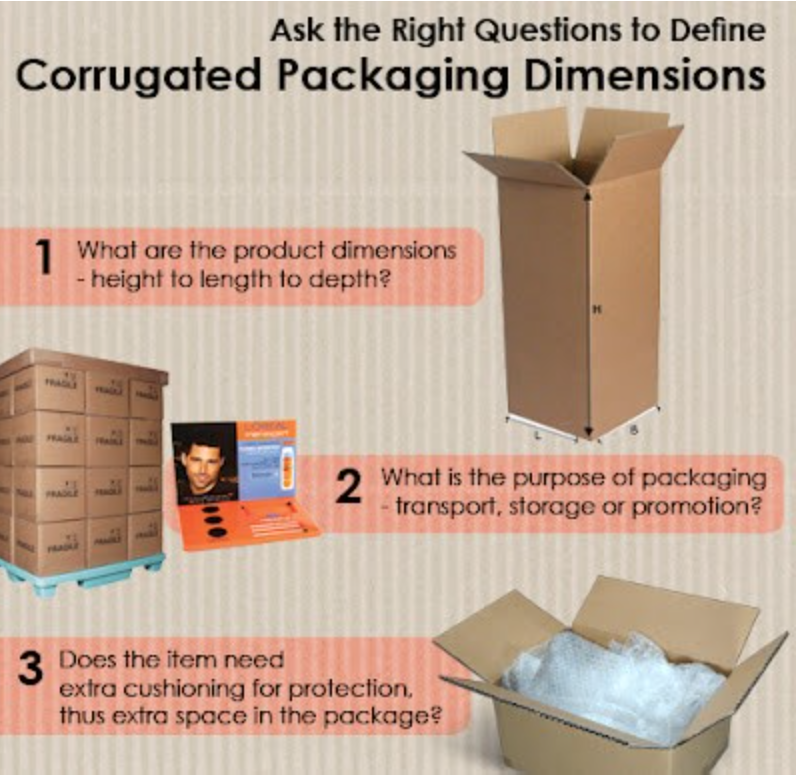

Define the Right Packaging Dimensions

Selecting the appropriate packaging dimensions is crucial to ensure sufficient protection and safe delivery of products to the appropriate location. This in turn reduces damaging, product-returns, and unnecessary waste.

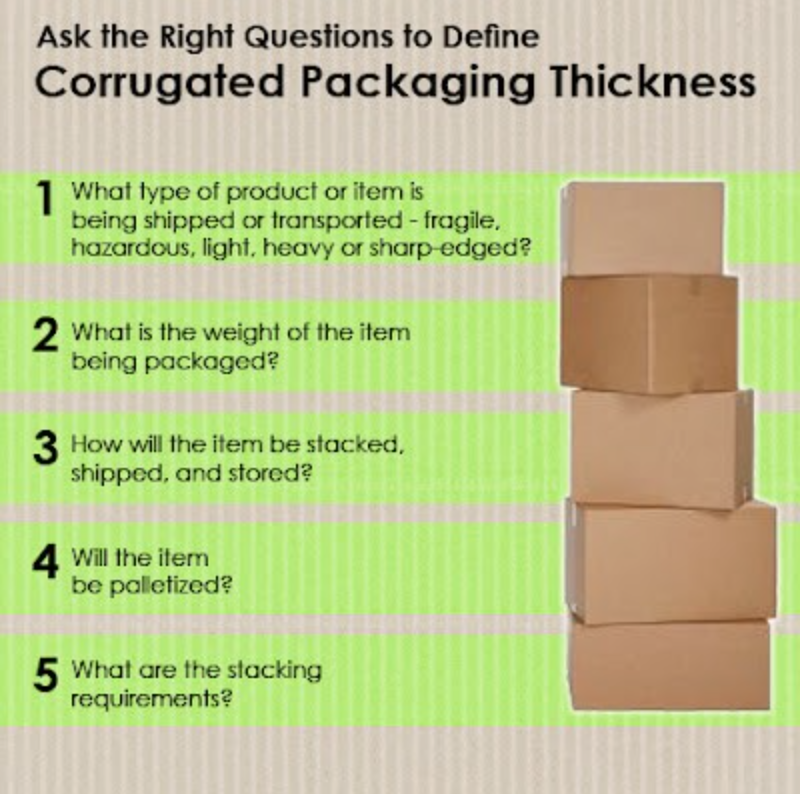

Define the Right Corrugated Packaging Thickness

Corrugated packaging comes in varying thickness, depending on the use. Heavier products need thicker, stronger and more durable corrugated packaging. Thus, to choose the right packaging one must first define the following:

Corrugated board comprises of two outer paper layers, known as linerboard, and a middle fluted material, known as corrugating medium or fluting. The thickness, strength, and use of corrugated packaging depend on the height of the medium, the paper type and weight, and the number of walls used: single wall, double wall, and triple wall.

The weight and fragility of the product, as well as the type of printing that will be used, determine the right combination of corrugated medium and layer to effectively pack and protect the product.

1. Corrugating Medium

There are different types of corrugating medium, most commonly: A, B, C, E, F and flute.

F flute, most applicable to consumer goods shelf packaging, offers extra stiffness and strength over solid board. Good for promotional purposes with high resolution printing, due to the thin medium (fluting).

E flute, most applicable to consumer goods shelf packaging, provides high resistance to flat crushing and inflexible in both directions. Due to thinness, the medium offers good printability with most commercial printing processes.

B flute, has relatively good stacking strength, high resistance to flat crushing, and saves space in comparison to A and C flute. Good for transport.

C flute, most used type of corrugated medium, is stiff and offers good stacking strength. Good for transport.

A flute provides the best stiffness, good stacking strength, and requires relatively a lot of space due to thickness. Good for production, storage and transport.

2. Layers

Choose the Corrugated Packaging that Offers the Right Design

The design of a corrugated box comprises of two aspects, the structural aspect and graphic aspect. Both play an important as the final marketing effort for customers.

1. Structural Design

There is a vast array of corrugated packaging products available, each corrugated packaging specified to meet different packaging needs for varying products and sectors. The choice of structural design lies in the goal users aim to reach through the packaging, whether promotional or for transporting and shipping.

Promotional: Shelf ready packaging, promotional boxes, bag-in-box (BIB) cartons, corrugated carry cartons, etc…

Transport & Shipping: Corrugated base wrap, corrugated boxes, corrugated trays, industrial heavy-duty packaging, heavy-duty bulk bins, etc…

2. Graphic Design

Corrugated packaging that will be seen by the end-user from a distance of 2.5m and below need high resolution and attractive promotional designs. When the corrugated packaging will serve as a display at points of sale, placed on a shelf or in a supermarket, then it is key that the packaging product offer high printing and design capabilities.

Corrugated packaging that will serve as storage or only to transport does not need high resolution graphics. It would be more effective to choose the packaging design that best packs, protects, and transports the product without a high emphasis on printing capabilities.

Brief Overview

References:

http://www.superpages.com/supertips/corrugated-cardboard-boxes.html

http://www.bascousa.com/customer-tools/articles/how-to-choose-the-right-corrugated-box-for-shippin.html

http://www.aiccbox.org/Industry/industry.asp

Live Feed

Live Feed Live Feed

Live Feed